In the maritime and shipbuilding industry, the process of designing and constructing vessels is an complex process between engineering precision, aesthetic appeal, and functional requirements. While it’s an exciting endeavour, it’s not without risks. These risks can lead to budget overruns, costly rework, and potentially dangerous design flaws. This is where 3D modelling emerges as a lifeline, providing an essential service that significantly de-risks the entire production process.

De-risking Through Precision:

Ship design demands an unparalleled level of precision. The smallest miscalculation or design oversight can have catastrophic consequences. Traditional design methods, often relying on 2D blueprints, left plenty of room for errors. However, 3D modelling brings a new level of accuracy to ship design.

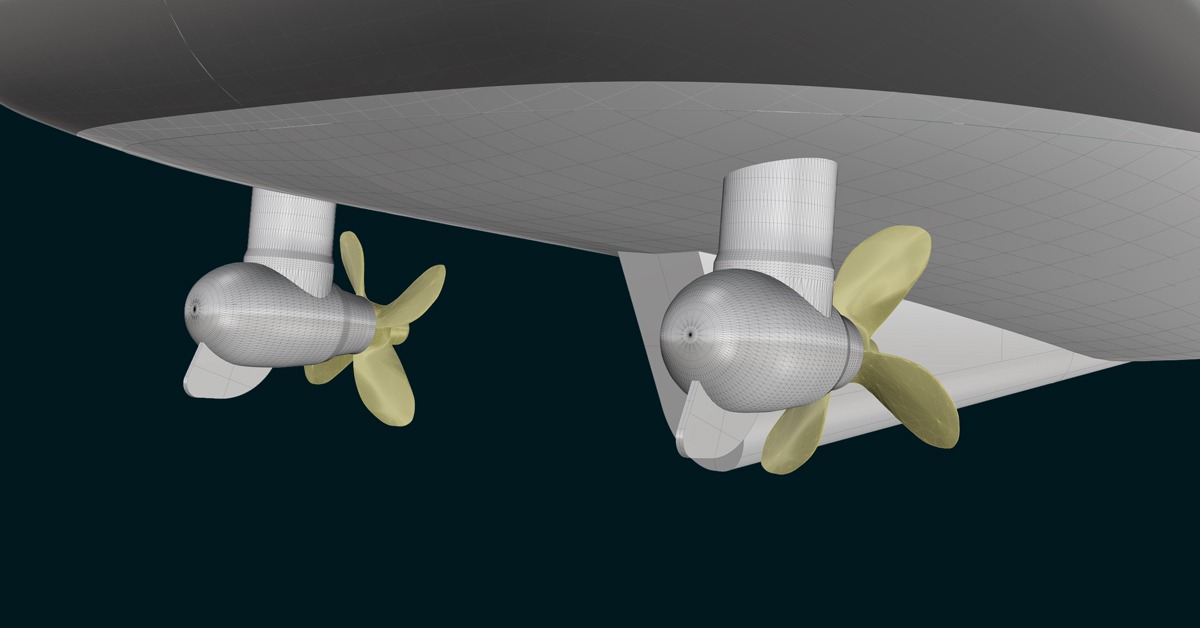

Through 3D modelling, engineers can create highly detailed digital representations of the vessel, capturing every angle, dimension, and component. This precision reduces the margin for error, identifying design flaws or inconsistencies at the earliest stages of the process, ensuring a safer and more reliable end product.

Visualizing the Future by 3D modelling

The maritime industry isn’t just about engineering; it’s also about fulfilling the vision of the client. Ship owners and stakeholders want to see the proposed vessel as clearly as possible before production begins. 3D modelling offers a level of visualization that traditional methods simply can’t match, reducing the risk of client dissatisfaction and costly design changes.

Enhanced visualization

Imagine being able to walk through a digital representation of your future ship, exploring every nook and cranny before a single piece of steel is cut. 3D modelling makes this possible. It allows clients and stakeholders to have a 360-degree view of the vessel, providing them with a tangible understanding of what they are investing in. This level of visualization helps clients make informed decisions early in the process, reducing the risk of costly alterations down the line.

Engaging Stakeholders for Risk Mitigation

In shipbuilding, collaboration and communication with various stakeholders are paramount. But traditional methods of conveying designs through flat blueprints or written descriptions often left room for misunderstandings and misinterpretations. 3D modelling resolves this challenge, facilitating collaboration and reducing the risk of miscommunication.

Collaboration and Risk Mitigation

3D models are an excellent tool for engaging stakeholders, from naval architects to construction teams. They provide a common ground for discussion and decision-making, ensuring that everyone is on the same page. Misunderstandings are minimized, and changes can be made more efficiently and cost-effectively.

In the maritime and shipbuilding industry, 3D modelling has proven to be a powerful risk mitigation tool. It enhances precision, provides clients with better visualization, and fosters improved collaboration among stakeholders. By de-risking the production process, 3D modelling sets sail towards a more efficient, cost-effective, and safer future for shipbuilding.

More articles