🇳🇱 Lees dit artikel in het Nederlands

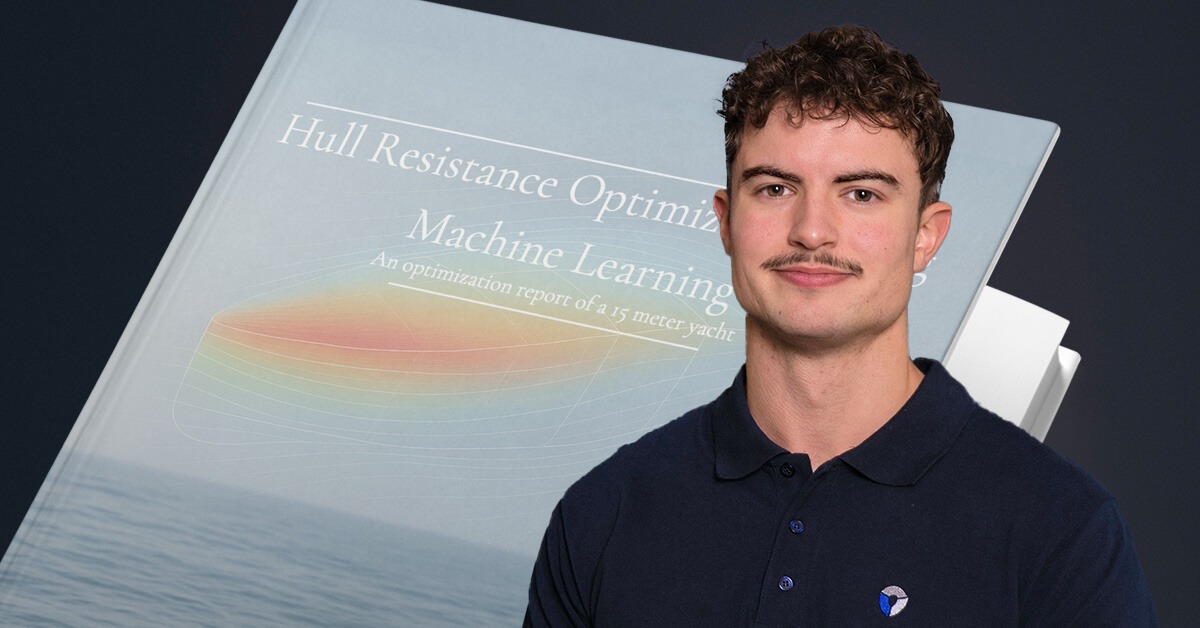

Scott van Hagen proudly displays a screen full of simulations. To the untrained eye, all hulls look nearly identical. But every curve, every angle, every small deviation reflects hours of testing, tweaking, and sometimes starting over. Subtle details make the difference between drag and efficiency.

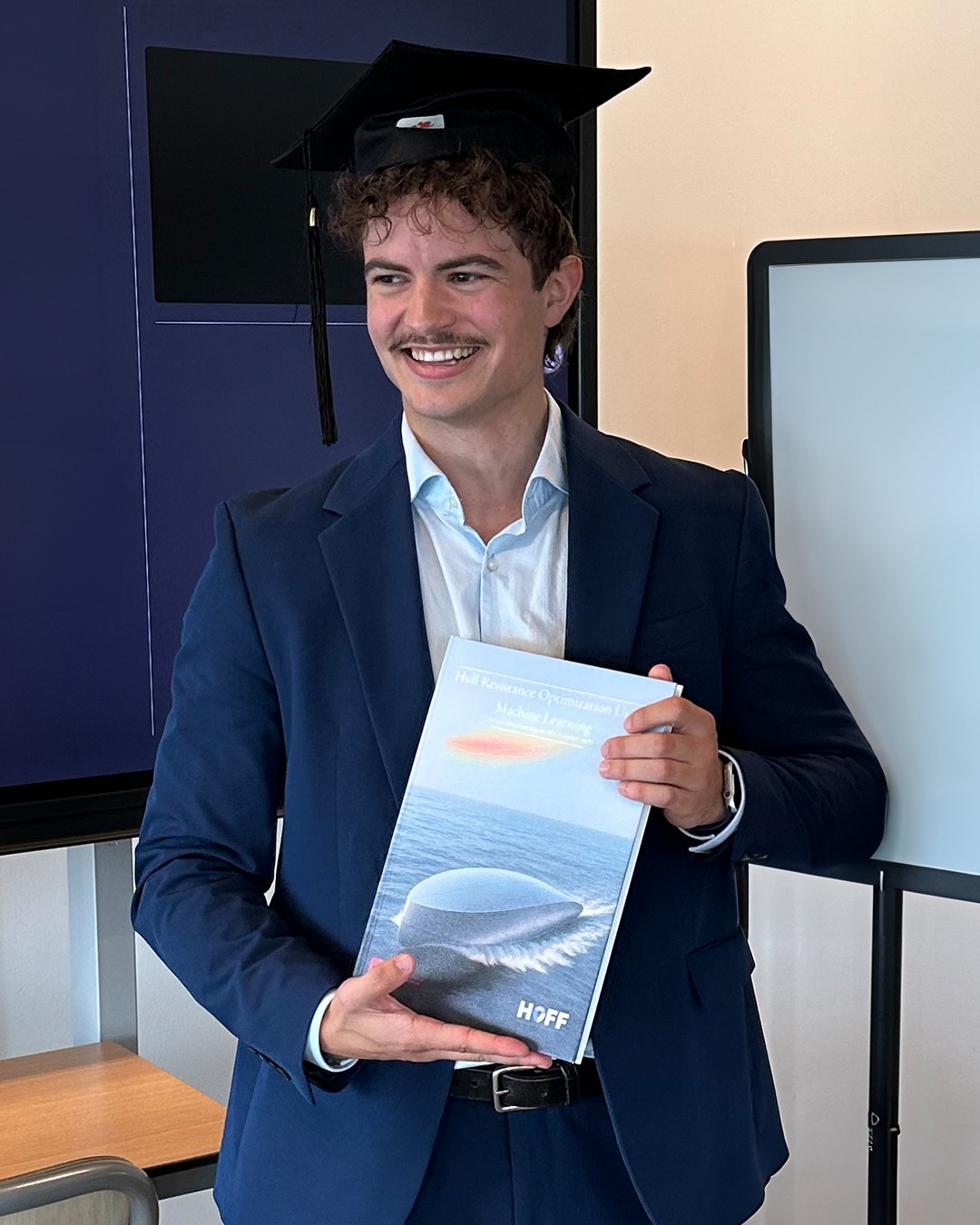

Scott recently completed his graduation project at HOFF, an engineering firm based in Papendrecht with deep roots in luxury yacht engineering. His research, Low-Speed Hull Form Optimization for Hybrid Yachts, focused on a technically specific yet commercially relevant challenge: how to optimize the hull shape of a 15-meter yacht for low-speed cruising, specifically around 6 knots, as required for electric propulsion in zero-emission zones.

A study that delivers a practical and tangible contribution to the sustainability of vessels, particularly in the luxury yacht sector.

From Technical Sideshow to Core of the Project

When Scott started, he had no idea how deep he would dive. What began as a side tool quickly grew into the core of the entire research.

“At first, I wanted to generate a series of hull variants to feed into a machine learning model,” he says. “The idea was to build a predictor based on geometry and drag. But when I saw how much small shape differences mattered, that part became the heart of my thesis. I had to understand what was really going on.”

He began by building a parametric hull in Rhino and Grasshopper, which he could control via 3 main parameters: block coefficient, transom width, and transom draft. To generate realistic and well-distributed variants, he applied Latin Hypercube Sampling. The result was a dataset of 50 unique hull shapes that collectively covered the design space in a representative way.

The Power and Limits of CFD

Each of those 50 hulls was simulated using Computational Fluid Dynamics (CFD) in ANSYS Fluent. The simulations took place in a virtual towing tank, under steady-state conditions and using a Shear Stress Transport (SST) k-omega turbulence model. For wave modelling, Scott used a Volume of Fluid (VOF) approach.

A key detail: Scott conducted a grid refinement study, systematically increasing mesh density to verify numerical accuracy. He calculated the Grid Convergence Index (GCI) to confirm his results were mesh-independent. This ensured reliable drag predictions, crucial for training machine learning models.

“It took me 3 months to get 1 good simulation running,” he says. “Not because the software couldn’t handle it, but because I had to figure everything out myself. I had to learn how to build a flow domain: where the flow enters (the inlet), where it exits (the outlet), and how to set boundaries so the simulation stays realistic. Also, how to model the boundary layer around the hull, that thin layer where flow and resistance interact. If you get that wrong, your drag prediction is worthless. It was technically complex and often frustrating, but essential to the result.”

The review panel assessed the thesis as a strong piece of research.

Smart Combination of Simulation and Data

Running a full sweep of 400 hull variants via CFD alone was unfeasible. Too time-consuming. Too expensive. But Scott saw that limitation as an opportunity for innovation. By combining his CFD results with machine learning, he managed to build a powerful prediction model. He trained 4 different algorithms: Linear Regression, Ridge Regression, Random Forest, and XGBoost.

In the end, the Ridge Regression model offered the best balance between reliability and simplicity. The input was purely geometric, based on the 3 parameters he defined in the parametric design. Based on that, the model predicted drag in Newtons at a speed of 6 knots.

To verify accuracy, he simulated the design with the lowest predicted drag again in CFD. The deviation was less than 1 percent. A clear signal that this approach works. And more importantly, it is reproducible.

“The beauty is that you can now evaluate other designs very quickly,” says Scott. “Once you input a design with known geometry, the model predicts resistance in seconds. That saves a massive amount of computing time. You no longer need to run new CFD simulations each time, which normally takes hours. The model acts like a smart assistant in the early design stage. It helps you make informed decisions before diving into deep simulations or physical testing.”

Gains Below the Waterline

The optimized hull yielded a 7 percent reduction in drag at 6 knots. Visually, the yacht barely changed. But below the surface, resistance dropped thanks to a combination of subtle adjustments: a flatter bottom that generates fewer waves, a shallower and narrower transom that calms the wake, and a more slender midship area that reduces wetted surface.

For a hybrid yacht, these are direct advantages: less battery capacity needed, lower overall weight, greater range, and reduced energy costs. Especially in urban zero-emission zones, where silence and efficiency are key, this optimization can be the difference between feasible and impractical.

A Welcome Distraction During the Research: Ironman

“Did I have rituals? Definitely. I have been training for a triathlon for almost a year. First, a good workout, then straight into the research.”

That physical routine helped him stay grounded during the tough parts of his graduation project. And HOFF’s support made a difference too, says Scott. “The guys at HOFF were incredibly supportive and fully backed the project. That really gives you a boost.”

A Foundation for Further Research

What Scott developed is not an endpoint but a beginning. He believes that the combination of parametric design, CFD validation, and early-stage machine learning adds real value. The approach is scalable and the results can be built upon.

“Many designs are based on existing hulls, with some modifications. I have shown that you can start differently and built something that works and can be further developed by HOFF and others.”

Want to know more about this research? Feel free to contact Scott van Hagen at +31 (0)85 060 4633.

More articles