When Jelmer de Jong started his graduation internship at HOFF, he took a fresh look at a familiar process. The basic structure of a yacht hull has been designed in much the same way for decades. But in a sector where speed, reliability and adaptability are essential, Jelmer saw room for smarter design. Not a revolution, but a clear improvement. Exactly the kind of development HOFF thrives on as a technical partner.

The idea was simple, the execution was not: could a tool accelerate hull structure design without compromising quality or technical accuracy? And just as important: could such a tool integrate smoothly into an existing workflow at a shipyard or engineering firm?

“What struck me at HOFF is that everyone is constantly looking for smarter ways to work,” Jelmer says. “That motivated me to take a new look at familiar processes.”

Parametric thinking, made practical

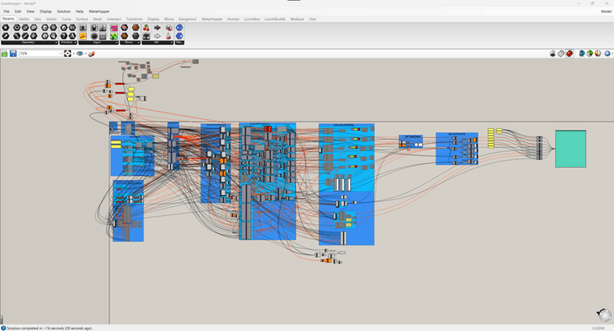

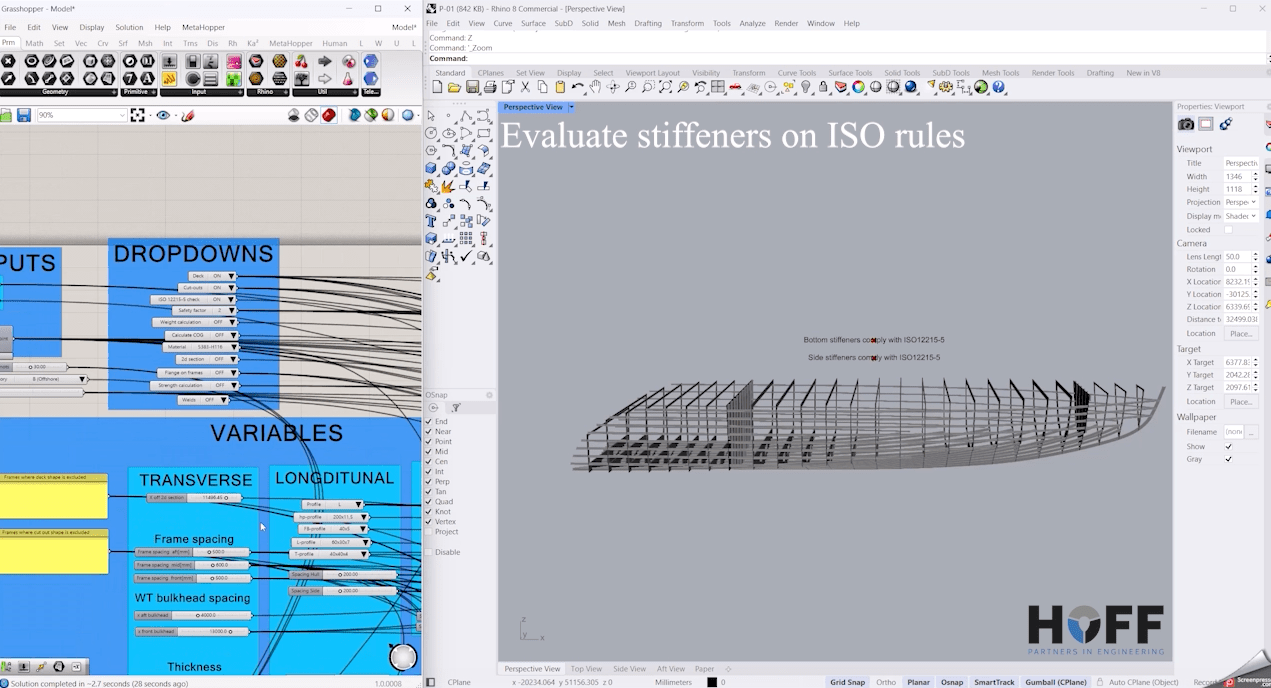

The tool Jelmer developed automates the generation of hull structures for motor yachts between 10 and 24 meters. Built in Rhino and Grasshopper, it uses parametric input: hull geometry, profile type, material, and frame spacing. The tool instantly converts this input into a 3D construction model, which is then evaluated for weight, center of gravity and ISO 12215-5 compliance.

“It’s made up of thousands of interconnected blocks,” says Jelmer. “Change one value, and the entire structure adjusts. It sounds simple, but there are over 6000 components running underneath.”

This connectivity is what gives the tool its strength: the model remains consistent even after major changes. Instead of redrawing, the structure is regenerated automatically. It’s faster, but also reduces the chance of errors. And users don’t need to be programmers. With the right input, a complete base structure can be generated within seconds.

Currently, the tool focuses specifically on the hull. But there are already ideas to expand it toward the superstructure, net spacing (which reserves space for interior layouts), and even piping systems. It opens up the perspective of a fully parametric yacht design, where multiple disciplines converge in a single model.

More control, less time

The real advantage lies in the flexibility. Every layout change can be implemented within seconds. What would normally take days to remap and redraw, now becomes a direct insight. Design decisions can be tested immediately against technical constraints, giving engineers the data they need to make solid decisions early on.

For HOFF, it means better control at an early stage.

“The beauty of it is, you no longer have to start over when something changes,” Jelmer explains. “You just adjust an input value, and the structure rebuilds itself.”

That doesn’t just save time. It also prevents outdated versions or incorrect drawings from circulating within a project team.

On top of that, the generated model provides valuable early insight into production costs. The tool can extract weld lengths and profile counts, giving a first estimate of labor and material requirements. That makes it useful not just for design, but also for production planning.

A unique approach, tested in practice

Comparable tools? They proved hard to find, especially with the same level of scope and ease of use. Jelmer validated his tool thoroughly: 300 different hull geometries, with a 98 percent success rate. The few failures were mostly due to input mistakes or minor geometric conflicts. Issues that are easy to resolve.

The tool is intentionally focused on the basic stage of design. But it’s exactly in this early phase that the biggest gains are made: quick iterations, early error detection, and immediate insight into mass estimates. That makes it highly relevant for any firm working in a dynamic design context.

Driven by curiosity and engineering

Jelmer isn’t a traditional software developer. His background is in maritime engineering, and it shows. “I wanted to understand how a hull is built and learn how to automate that process. So I built it all myself.”

It wasn’t always easy. “The structural calculations were especially tricky. That’s really a specialty on its own. I eventually chose a simplified model, just accurate enough for this design stage.”

It meant a lot of trial and error. Testing, tweaking, and occasionally getting frustrated behind the screen. “But that’s part of it. If it had been easy, someone would’ve done it already.”

A valuable tool across the project

For engineers, this means faster iterations without the need to redraw manually. For design coordinators and project leads, it means quicker decisions and less downtime between design updates and structural validation. And for shipyards and suppliers, it means shorter timelines, fewer redesign risks, and a reliable foundation for production.

But the tool isn’t just about drawing. It’s about data. Mass estimates, strength indicators, part locations — it’s information other disciplines rely on to begin their own work. The earlier it’s available, the smoother the project runs overall.

“This tool doesn’t just help me as an engineer,” Jelmer says. “It helps colleagues in other disciplines who need input fast. That keeps the whole project moving.”

A project that continues within HOFF

What makes this project stand out isn’t just the result. It’s how HOFF embraced it. With frequent check-ins, founders Lars Hofman and Marcel Kruithof challenged not only the technical aspects, but also the practicality of the solution. “Without their guidance, the result wouldn’t have been as realistic,” Jelmer says. “They kept pushing me to ask: why are you doing it this way, and will it work in real projects?”

The tool is now part of HOFF’s internal knowledge development, with further iterations being explored by Jelmer and the team.

What started as a curious idea became a usable tool — one that continues to evolve within the team. “There’s still plenty to add,” Jelmer reflects. “But this is a solid start.”

Would you like to know more about this research? Feel free to contact Jelmer de Jong at +31 (0)85 060 4633.

More articles