We’re seeing it more and more: shipyards involving us earlier in their projects. Not just because it helps spread the workload, but because it simply works better. Less hassle. Fewer surprises. More predictability. The way you approach the basic engineering phase often determines how much control you’ll have over everything that comes after. That’s exactly where the real benefits start.

This article explains why it pays to treat engineering as more than just technical work, and how to do that without disrupting your way of building.

Not just output, but direction

The basic engineering phase sets the tone for the entire build. Sure, it’s about drawings, diagrams and models. But what you’re really creating is direction, a foundation for everyone else to build on. If that base is solid, everything that follows becomes easier. Fewer questions. Fewer last-minute changes. Less need for clarification. That’s why this phase isn’t just about technical accuracy. It’s also about:

• alignment between disciplines,

• practical usability for procurement and production,

• and clearly documented decisions and design assumptions.

When that’s in place, things run smoothly. If not, issues tend to pop up later, when they’re harder and more expensive to solve.

Basic engineering defines the space for error, or for control

A lot of late-stage discussions can be traced back to minor issues here:

• routing that turns out to be impractical,

• models that are open to interpretation,

• or sequencing that doesn’t reflect how the ship is actually built.

These aren’t big mistakes, but they can have major knock-on effects. Small misalignments upstream can lead to quick fixes onsite, which then impact installation, procurement or certification. Talking through these risks early makes a real difference. It gives space to consider both technical detail and practical implications.

That’s where we add value. Not just by delivering engineering packages, but by helping structure the project.

Creating structure in complex projects

Projects are getting more complex. Clients want to change things late. Suppliers have their own lead times. Teams rely on each other’s progress. Meanwhile, the schedule keeps moving.

Our method is built to create clarity in that complexity. Not by locking everything down too early, but by giving structure and space for iteration.

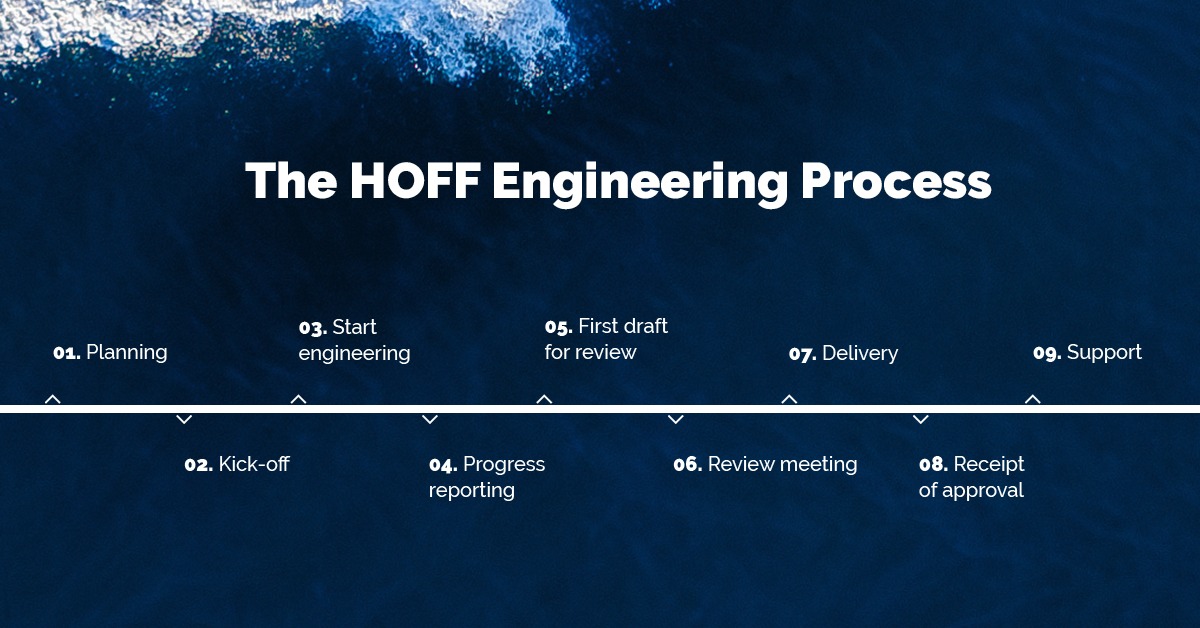

Our approach (click for more):

• surfaces risks early,

• keeps coordination simple and relevant,

• and makes change manageable when it does happen.

It helps you stay in control, even when the project shifts.

An engineering partner who fits into how your yard works

Engineering gets complicated when it doesn’t match the way your yard operates. Even if the model is technically correct, it might not be practical. A design can meet all the specs and still not work in your production flow. That’s why it helps to work with a partner who doesn’t try to change how you work, but connects to it.

Over the years, we’ve worked with many different software systems and workflows. Because of that, we can almost always plug in straight away, no need to adapt your entire process. We bring structure that fits the way you already build, so things keep moving without disruption.

It’s an effective and lower-risk way to manage your build.

Let’s set course

Already working with us and want to shift earlier in the timeline? Or looking for clarity before your next build?

Let’s talk. Contact Lars Hofman of Marcel Kruithof via 085 060 4633

More articles